What makes a product sustainable?

Ceramics tile production relies heavily on the use of raw materials and natural energy resources. Consumers worldwide are becoming increasingly aware of the impact on the environment their lifestyle choices have.

Designers and Architects are increasingly focusing on constructing greener buildings and demanding better environmental practice. However many of our fixtures and fittings are produced using unsustainable methods and shipped from across the globe.

A product is considered sustainable if the process used to source, manufacture and distribute could go on indefinitely with little negative impact on the environment. Two & A Half Dimension believes this definition should always extend to include sustainable and humane worker practices.

How are handmade ceramic tiles made?

Ceramics have changed very little since 3,500 BCE. This is because ceramics create a product when fire that have a durability and longevity allowing them to last a lifetime or longer. To this day, archeologists still unearth pieces of ceramics from thousands of years ago.

Ceramic tile production has changed a lot over the past hundred years, with mass industrialisation allowing tiles to be produced at an increasingly faster pace. However, the process itself remains almost the same, although we are now able to produce much more durable ceramic tiles.

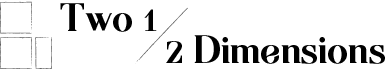

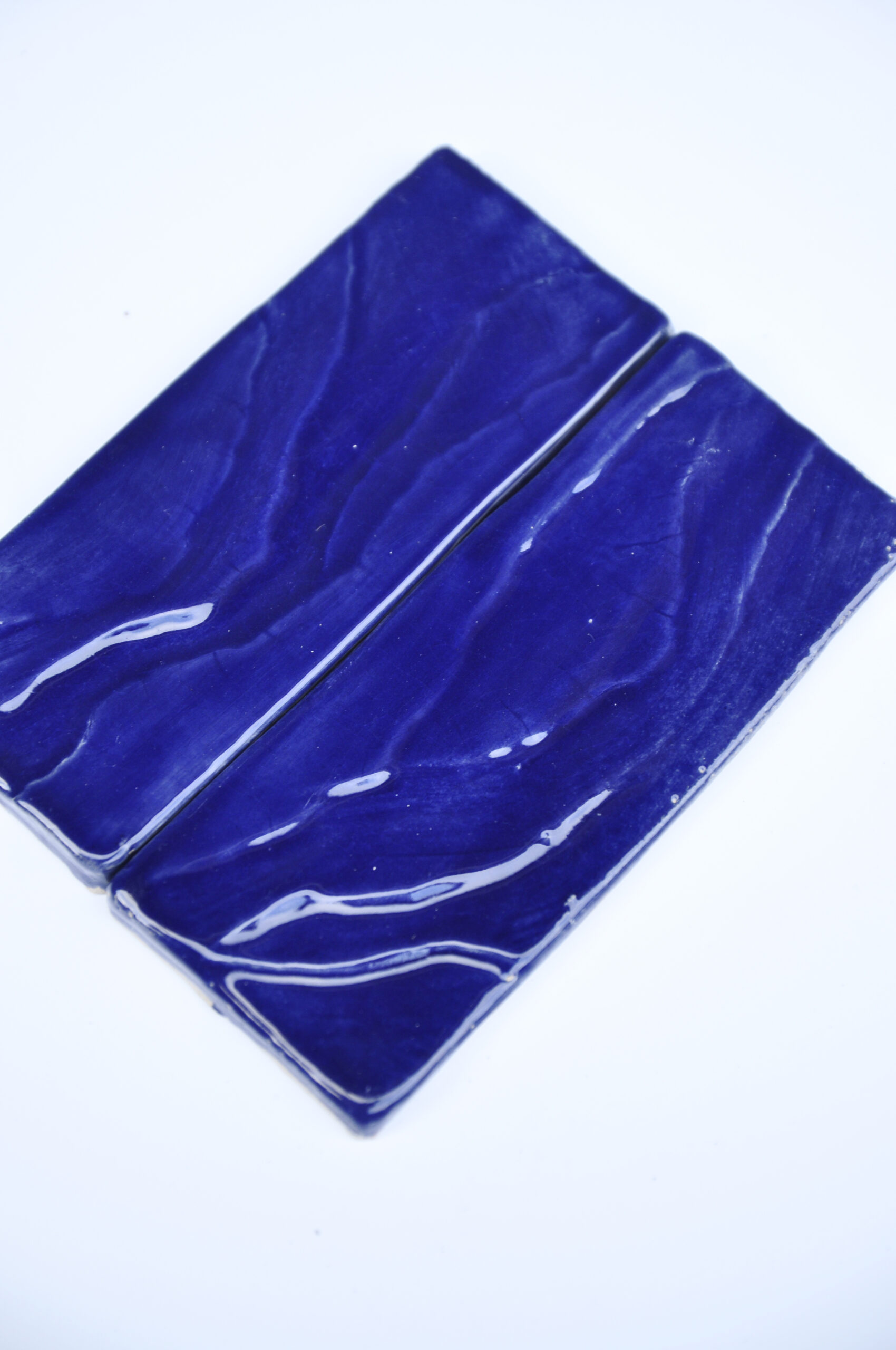

Mineral bodies in ceramic clay are abundant and sourced from the earth. The difference between industrial and handmade ceramic tiles lies in the use of moulds and robotics. Our tiles are hand cut and left to dry for approximately a week (depending on the weather) before going through an initial biscuit firing at 1090℃. They are either sealed using boiled linseed oil, or are hand glazed and go through a second glaze firing at 1040℃. This creates a vitrified glass layer that prevents water from penetrating the surface.

How do you make kiln firings sustainable ?

All of our tiles use low fire earthenware clay. These take considerably less energy to fire as the kiln timings can be as low as 8 hours. Earthenware uses a much lower quantity of energy to vitrify.

Where possible, single firing handprinted tiles helps reduce firing time. By using electric kilns rather than gas kilns, we also have a cleaner firing.

Many larger operations save further energy by redirecting excess heat from kilns into studio boilers or heaters to reduce their carbon footprint. By taking advantage of existing energy cleverly they also reduce costs. This is on our own list for when the studio becomes large enough to make such changes.

Community engagement and sustainability with ceramic tile production

For our handmade tiles to be truly sustainable, they must also engage with the local community. We are a small group of skilled local craftspeople in Italy, Naples, who are paid fair wages and have good working conditions. Using these traditional techniques we create beautiful unique heritage tiles.

Employing local artisans is a vital form of sustainable community building and integration.

Health and Safety in ceramic tile studios

It is important to your studio is a safe environment. In our studio our priority is our artisan tile makers. Dry clay dust and glaze can cause silicosis, so we ensure that we clean using water rather than sweeping on a daily basis.

Another concern with ceramic sustainability is glazes: all of our glazes contain no lead, cadmium or barium as these glazes can leech into our water sources and cause irreparable environmental damage.

Recycling and sustainability

Unfired clay and glaze is a resource that can be reused indefinitely. Within our studio all broken tiles, slurry and trimmings are rehydrated and wedged together and reused. All glaze brushes are washed in an area where water is left to settle; the water is then poured off and glazes recycled.

All our resources are sourced within the UK and locally where possible. For example, our clay comes from Staffordshire, which reduces road miles and associated carbon output.

A method to reuse fully fired broken ceramics is to keep them aside for mosaic artists to collect. They can also be used as drainage at the bottom of flower pots.

Our commitment to a sustainable production

Two & A Half Dimensions offers pieces that are designed to last beyond your lifetime using sustainable production for both people and the environment. None of our tiles contain harmful chemicals like barium, cadmium or lead. All these factors contribute to the overall sustainability of our products.

Learn more about our products in our Frequently Asked Questions or Get in contact if you have any queries regarding our sustainable practices.