Part 1/2

Our Story

Piera Dencker-Rasmussen de Mascoli founded Two & ½ Dimensions in 2020, after a decade of experience in Architecture and Interior design. This studio specializes in handmade artisan ceramic tiles, priding itself on crafting each tile by hand. After working in a tile making studio in the Aeolian Islands, Piera noticed that handmade tiles were often imported and machine cut, even in traditional artisanal studios.

Wanting to revive this craft, she established the studio to produce tiles entirely by hand, from shaping to glazing. By blending her Danish and Italian heritage, Piera aims to preserve artisanal techniques while embracing modern design. The studio is now based in Naples.

Part 2/2:

6-10 weeks lead time

Our Process

1 – Planning

Before we start any project, we’ll discuss with you how to figure out exactly what your space needs. We can even calculate things like width, grout, and quantities, and come up with some layout ideas. It’s all customized to fit your style and schedule, so we’ll make sure to work around your timeline. Plus, if you need some visuals, we can create some drawings to help you see the whole picture.

2 – Preparation

We start by preparing our clay. Our clay is wedged to remove air bubbles as all our clay is constantly in a cycle of being recycled and rehydrated within the studio until used up.

3 – Rolling

Our clay is then rolled out. This is all done by hand, using a mixture of rolling pins and slab rolling machines.

6 – Sealing

If you have chosen to use unglazed tiles, we will either seal them with Boiled Linseed oil (please see more information on the Choosing Your Tiles page), or a chemical sealant. This helps protect them against damage and water absorption.

5 – Bisque Firing

Your tiles are then fired up to 1020°c over a period of 12 hours. This helps them transform from delicate clay to hard tiles.

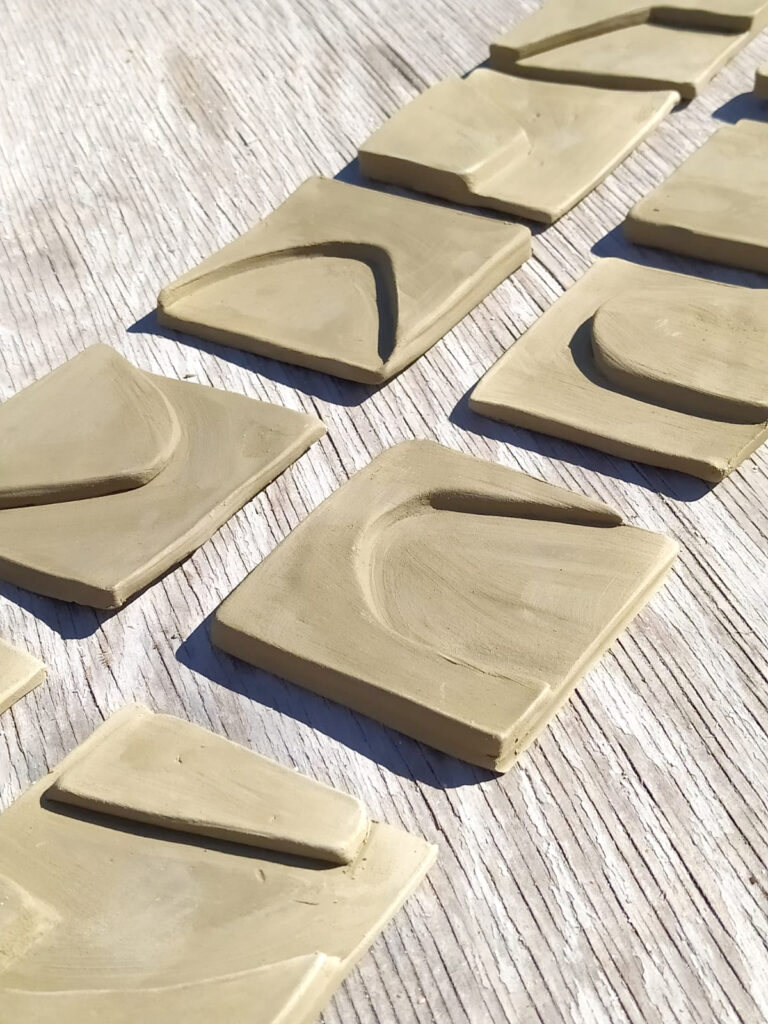

4 – Drying

Your tiles then take approximately 3 weeks to dry. We are lucky to be in the beautifully sunny city of Naples, so we may even dry your tiles in the sun! This drying time is crucial: we do not produce on an industrial scale, so for tiles not to warp or crack they need to dry slowly.

7- Glazing

If you have chosen glazed tiles, we then hand glaze our tiles. This technique means that subtle variations will appear on your tiles, with the % depending on how volatile your chosen glaze is.

8 – Final Firing

Your tiles are then fired again, up to 1050°c over a period of 12 hours. This helps melt the glaze, sealing it to the surface of the ceramic. This creates a waterproof tile. With some of our tiles, we do a 3rd firing at 800°c for enamel finishes.

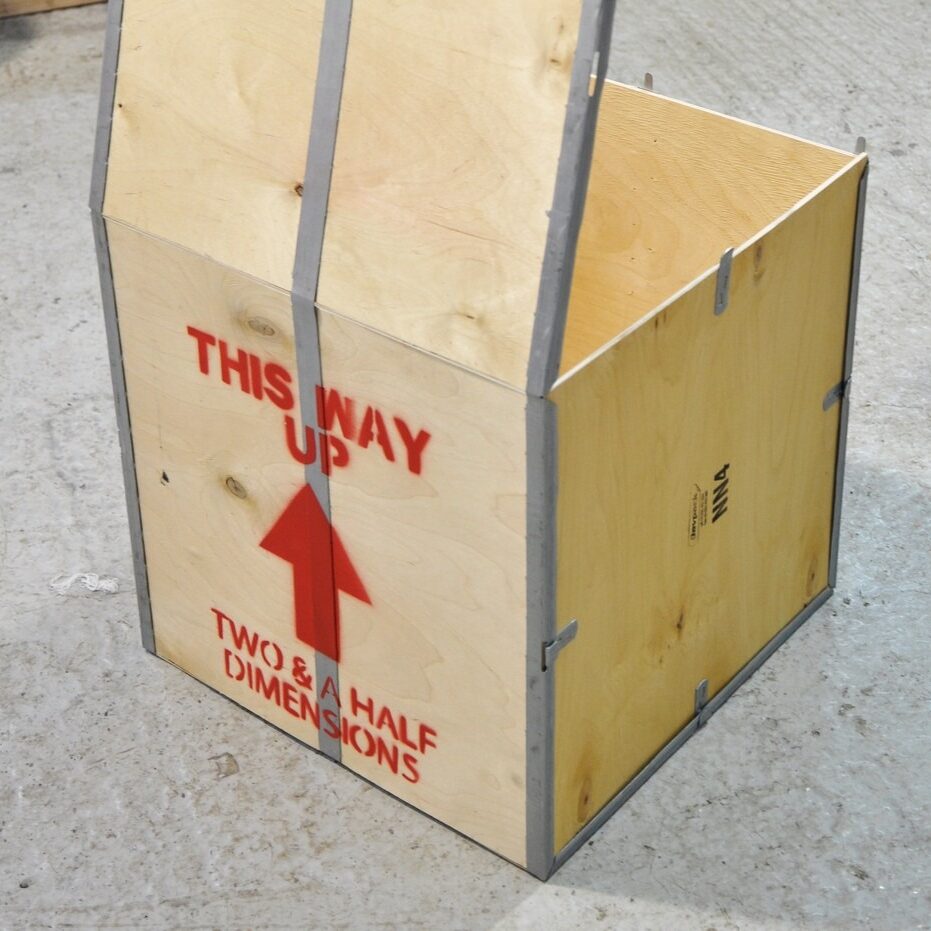

9 – Pack & Send

We pack all of our tiles individually, and for large orders we use wooden crates made by our local carpenter.

Ethos

At Two & A Half Dimensions, we have always understand that as artisans, our ability to create and thrive is inherently linked to nature and society. It is not possible for us to exist without happy artisans who are paid fairly and treated with dignity. Moreover, we rely on raw materials that the earth provides us. We must work in harmony with it, which is why all our work is made to order. None of our raw materials are toxic, and all products are locally and ethically sourced saving on road miles and therefore emissions. We specifically fire at temperatures that can provide strong tiles without costing the environment.